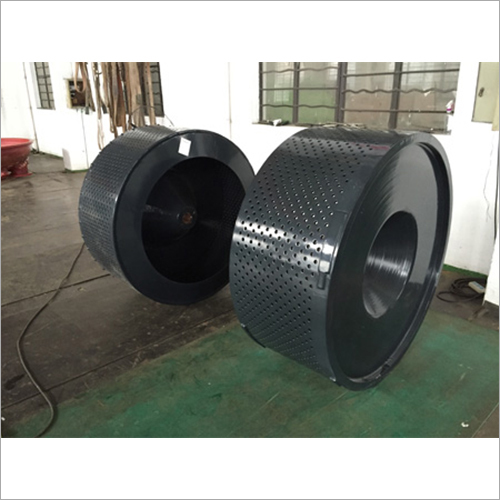

Dynamic Balancing Machine

Dynamic Balancing Machine Specification

- Display Type

- Digital Display

- Automation Grade

- Semi-Automatic

- Temperature

- Ambient

- Orientation

- Horizontal

- Efficiency

- 95%

- Power Source

- Electric

- Usage & Applications

- Rotors, Impellers, Blowers, Shafts, Couplings, Rollers, etc.

- Instruments Type

- Industrial Precision Balancer

- Sensor Type

- Piezoelectric Transducer

- Measurement

- Unbalance, Vibration Level

- Product Type

- Dynamic Balancing Machine

- Material

- Mild Steel Body

- Cooling System

- Air Cooled

- Noise Level

- <70 dB(A)

- Reactor Thickness

- 12 mm

- Processing Time

- Configurable

- Capacity

- Up to 2000 kg

- Voltage

- 220V / 380V, 50Hz

- Weight

- 1200 kg

- Dimension (L*W*H)

- 2100 x 700 x 1100 mm

- Surface

- Powder Coated

- Data Output

- USB / Printer Port

- Safety Features

- Emergency Stop & Protective Guards

- Drive System

- Belt Driven

- Balancing Speed

- 200-2000 RPM

- Rotor Diameter

- Up to 1800 mm

- Balancing Accuracy

- 1 gmm/kg

- Fixture Type

- Universal Chuck

- Operating Temperature

- 5°C to 45°C

- Control Panel

- Microprocessor-Based

- Clamping Method

- Dynamic End Drive

Dynamic Balancing Machine Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 5-7 Days

About Dynamic Balancing Machine

A dynamic balancing machine is a machine used to measure and correct an imbalance in rotating equipment. It is used to ensure that the weight of the rotating parts are evenly distributed, thus eliminating vibration and excessive wear on the rotating components. The machine provides a precise measurement of the imbalance, which can then be corrected with weights or other means.Precision Balancing for Industrial Rotors

Achieve top-tier balancing for various rotating equipment, including rotors, impellers, blowers, shafts, and couplings. The Universal Chuck and dynamic end drive system ensure flexibility and adaptability, while a digital display provides real-time measurement data. This machines horizontal orientation and semi-automatic design make it a reliable addition to any industrial setup.

Advanced Control and Safety Features

Benefit from a microprocessor-based control panel and configurable processing times for tailored performance. Safety is prioritized with emergency stops and protective guards. The mild steel body with powder coating and air-cooling system extends machine longevity, keeping operation safe and efficient within 5C to 45C.

Comprehensive Data Output for Analysis

Track and record balancing results via USB or printer port. The integrated piezoelectric transducer measures vibration and unbalance with high accuracy, facilitating detailed analysis and quality assurance. The machines capabilities are fully suited for distributor, manufacturer, and service provider requirements, ensuring seamless integration into industrial processes.

FAQs of Dynamic Balancing Machine:

Q: How does the dynamic balancing machine achieve precise balancing accuracy?

A: The machine utilizes a microprocessor-based control panel and piezoelectric sensors to detect and measure unbalance and vibration levels. With balancing speeds of 200-2000 RPM and an accuracy up to 1 gmm/kg, it ensures precise correction for industrial rotors and components.Q: What components can be balanced using this machine?

A: It supports balancing of various rotating parts such as rotors, impellers, blowers, shafts, couplings, and rollers, accommodating diameters up to 1800 mm and weights up to 2000 kg, making it versatile for multiple industrial applications.Q: When should industrial users opt for this balancing machine?

A: This machine is ideal when high balancing efficiency and accuracy are required, especially for heavy and large-diameter components. It is suitable for routine maintenance, manufacturing, and service operations, enhancing equipment lifespan and performance.Q: Where is the machine commonly installed and operated?

A: It is typically installed in manufacturing plants, maintenance workshops, and fabrication units across industries in India. Its robust design, moderate dimensions, and powder-coated finish make it suitable for diverse operational environments.Q: What is the process for balancing rotors using this equipment?

A: Users mount the rotor to the universal chuck, configure settings on the digital control panel, and initiate the balancing cycle. The machine detects unbalance through piezoelectric sensors and displays correction information in real time, with options to save or print data for documentation.Q: What are the operational benefits of the machines built-in safety features?

A: Emergency stop functions and protective guards safeguard operators during the balancing process, reducing risk and supporting compliance with stringent safety standards in industrial applications.Q: How does the machine integrate with modern data analysis methods?

A: Data output capabilities through USB and printer ports enable direct transfer of balancing results to computers or printouts, facilitating easy integration into quality assurance workflows and further analysis for process optimization.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dynamic Balancing Category

Leth Work

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Noise Level : Low

Capacity : 15 Ton/day

Voltage : 220 Volt (v)

Product Type : Leth Work

Center Balancing Machine

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Noise Level : <70dB

Capacity : 10300 kg

Voltage : 380V / 220V, 50Hz

Product Type : Center Balancing Machine

Dynamic Center Balancing Machine

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Noise Level : 70 dB

Capacity : Up to 200 kg

Voltage : 380V / 50Hz

Product Type : Dynamic Center Balancing Machine

FRV Ampiler

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Noise Level : Less than 65 dB

Capacity : 250500 Litre

Voltage : 220240 V

Product Type : FRV Amplifier

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS