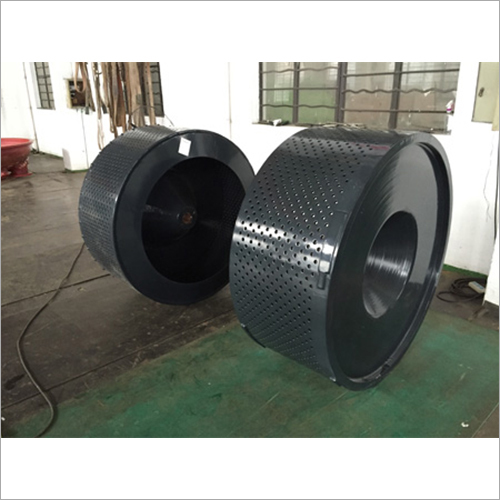

Center Balancing Machine

Center Balancing Machine Specification

- Automation Grade

- Automatic

- Orientation

- Horizontal

- Temperature

- 0C to 45C

- Display Type

- Digital Touch Screen

- Efficiency

- >98%

- Power Source

- Electric

- Scrubber Type

- Dry Type

- Usage & Applications

- Wheel, Rotor, Pulley Balancing

- Sensor Type

- High Precision Vibration Sensor

- Instruments Type

- Measurement and Calibration Equipment

- Measurement

- Dynamic and Static Balancing

- Product Type

- Center Balancing Machine

- Material

- Mild Steel, Powder Coated

- Cooling System

- Air Cooled

- Noise Level

- <70dB

- Reactor Thickness

- 8mm

- Processing Time

- 30-45 seconds per cycle

- Capacity

- 10-300 kg

- Voltage

- 380V / 220V, 50Hz

- Weight

- 850 kg

- Dimension (L*W*H)

- 1800 x 1050 x 1300 mm

- Surface

- Powder Coated Finish

- Min Workpiece Length

- 60 mm

- Data Output

- USB, RS232

- Protective Cover

- Included

- Imbalance Indication

- Digital, Simultaneous in Two Planes

- Supporting Roller Material

- Heat-Treated Steel

- Foot Mounting

- Anti-vibration Pads

- Max Workpiece Diameter

- 1600 mm

- Min Workpiece Diameter

- 60 mm

- Operating Humidity

- 85% RH

- Max Workpiece Length

- 2000 mm

- Clamping Method

- Universal Self-centering Chuck

Center Balancing Machine Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 5-7 Days

About Center Balancing Machine

A center balancing machine is a type of balancing machine used to measure the static and dynamic balance of a rotating object, such as a motor shaft or tire. The machine can be used to measure the balance of an entire assembly or individual components. The machine typically consists of a rotating table that is driven by an electric motor. The object to be balanced is placed on the table and the machine then measures the amount of imbalance in the object. The imbalance is then corrected by adding or subtracting weights to the object. The machine is typically used in industries such as automotive, aerospace, and military.Precision Balancing for Diverse Applications

This machine addresses the precise balancing of wheels, rotors, and pulleys with remarkable efficiency. Its automated process, digital touch display, and dual-plane imbalance indication enable operators to achieve accurate results. With support for a wide range of workpiece sizes and weights, it meets industrial demands in manufacturing and calibration environments, ensuring optimal performance and longevity of rotating components.

Robust Build and User-Centric Design

Crafted from powder-coated mild steel and equipped with anti-vibration mounting, the machine guarantees durability and minimal noise (<70dB). The inclusion of a protective cover and heat-treated supporting rollers further ensures both operator safety and material integrity, accommodating the rigors of high-volume industrial use.

FAQs of Center Balancing Machine:

Q: How does the Center Balancing Machine ensure precise balancing of rotors, wheels, and pulleys?

A: The machine uses high precision vibration sensors and a universal self-centering chuck to detect and correct imbalances simultaneously in two planes. Its digital touch screen provides clear indications and data outputs, ensuring accurate balancing every cycle.Q: What is the typical processing time for a balancing cycle with this machine?

A: Each balancing cycle takes approximately 30 to 45 seconds, delivering rapid and reliable results suitable for both high-volume and detailed calibration tasks.Q: When should this equipment be used for dynamic and static balancing?

A: It is recommended to use the machine whenever you need to ensure optimal rotation and longevity of components such as wheels, rotors, and pulleys, especially during manufacturing, maintenance, or quality control processes.Q: Where can the Center Balancing Machine be installed?

A: This balancing machine is designed for horizontal orientation and is well-suited to factory floors, calibration labs, and service workshops. Anti-vibration foot pads and a robust frame make installation straightforward and stable on any level industrial surface.Q: What are the benefits of the machines digital touch screen and data output features?

A: The digital touch screen offers intuitive operation and real-time monitoring, while USB and RS232 data outputs enable seamless integration with quality control systems, facilitating efficient documentation and analysis.Q: How does the protective cover enhance safety during operation?

A: The included protective cover shields operators from moving parts and debris during balancing, preventing accidents and ensuring compliance with workplace safety protocols.Q: What advantages does the air-cooled system offer for continuous machine operation?

A: The air-cooled design maintains optimal operating temperature, allowing the machine to run reliably in environments up to 45C, thus supporting extended, consistent use without overheating.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dynamic Balancing Category

Leth Work

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Automation Grade : SemiAutomatic

Temperature : Up to 70C

Surface : Polished

Orientation : Horizontal

Dynamic Center Balancing Machine

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Automation Grade : SemiAutomatic

Temperature : 0~45C Operating

Surface : Powder Coated

Orientation : Horizontal

FRV Ampiler

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Automation Grade : Automatic

Temperature : 10C to +60C

Surface : Powder Coated

Orientation : Horizontal

FRV Moulded Ampiler

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Automation Grade : Manual to SemiAutomatic

Temperature : Operates up to 60C

Surface : Smooth, antistatic finish

Orientation : Vertical/Wall Mountable

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS