Fume Scrubbers

Fume Scrubbers Specification

- Instruments Type

- Gas Scrubber

- Sensor Type

- Gas & Flow Sensor

- Scrubber Type

- Wet Scrubber

- Temperature

- 0C 60C

- Measurement

- Air Quality / Gas Concentration

- Orientation

- Vertical

- Usage & Applications

- Chemical Industries, Laboratory Exhaust, Pharmaceutical Plants, Acid Fume Removal, Pollution Control

- Efficiency

- Above 95%

- Power Source

- Electric

- Product Type

- Fume Scrubber

- Material

- PP (Polypropylene), FRP (Fibre Reinforced Plastic), PVC

- Cooling System

- Water Based

- Noise Level

- < 60 dB

- Processing Time

- Continuous

- Dimension (L*W*H)

- Customized as per requirement

- Discharge Outlet Size

- As per demand

- Drain Facility

- Provided

- Emission standard compliance

- CPCB/ SPCB standard

- Corrosion Resistance

- Excellent

- Installation

- Easy to Install & Maintain

- Design

- Compact and Modular

- Application Area

- Industrial Exhaust, Laboratory, Manufacturing, Wastewater Treatment

Fume Scrubbers Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 5-7 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- polythene packing

- Main Domestic Market

- All India

About Fume Scrubbers

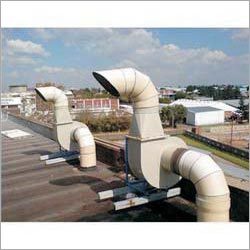

In abidance with the strict quality norms, we are manufacturing and supplying an excellent range of Fume Scrubbers. These systems find application in different industries to extract toxic, corrosive & hazardous fumes. Our Fume Scrubbers are broadly appreciated among our clients for features like less maintenance, high functionality and low power consumption. Made by using premium grade materials sourced from certified vendors, these systems are available in different sizes at nominal prices.

Specification

| Brand | Bindica Polyplast |

| Voltage | 110/220V |

| Automation Grade | Automatic |

| Material | PP, FRP |

| Airflow | 12000m3/H |

| Frequency | 50/60Hz |

| Country of Origin | Made in India |

'' We Are Mainly Dealing In Mumbai & Maharashtra ''

Superior Corrosion Resistance

Engineered from Polypropylene (PP), Fibre Reinforced Plastic (FRP), and PVC, these fume scrubbers resist harsh chemicals and corrosive gases. This construction not only ensures durability but also prolongs the systems lifespan, requiring minimal intervention for maintenance. Industries can rely on consistent performance even in challenging operational environments.

Effortless Installation and Maintenance

The modular, compact design facilitates quick and easy on-site installation, reducing downtime. Maintenance is simplified through accessible components, a provided drain facility, and water-based cooling systems, which contribute to steady operation and optimal emission control. This user-friendly design supports continuous industrial processes.

Compliant and Highly Efficient

Scrubbers are manufactured to strictly adhere to CPCB and SPCB emission standards, guaranteeing safe discharge of treated air. Equipped with gas and flow sensors as well as precision measurement instruments, they maintain air quality with more than 95% removal efficiency. Laboratory and industry operators benefit from reduced environmental impact and regulatory assurance.

FAQs of Fume Scrubbers:

Q: How are these fume scrubbers installed and maintained?

A: The scrubbers are designed for easy installation with their compact and modular build. Maintenance is straightforward due to accessible components, provided drain facilities, and high-grade corrosion-resistant materials. Most routine procedures involve simple inspections and water-based cooling system checks.Q: What types of materials are used in making these fume scrubbers?

A: These fume scrubbers are fabricated using high-quality Polypropylene (PP), Fibre Reinforced Plastic (FRP), and PVC, ensuring excellent resistance to corrosion, chemicals, and wear for longevity in industrial settings.Q: When should a fume scrubber be used in industrial processes?

A: Fume scrubbers should be utilized whenever hazardous gases, acid fumes, or pollutants are emitted during industrial processes, especially in laboratories, chemical industries, pharmaceutical plants, and wastewater treatment facilities, to comply with CPCB/SPCB standards and safeguard air quality.Q: Where can these fume scrubbers be applied?

A: The scrubbers are suitable for diverse settings, including industrial exhaust systems, laboratory ventilation, manufacturing plants, pollution control initiatives, and acid fume removal systems. Their customization capabilities allow adaptation to most facility layouts.Q: What is the process by which these scrubbers remove pollutants?

A: These wet scrubbers operate continuously using water-based cooling and a vertical orientation. Polluted air enters the system, where it interacts with water and chemical solutions. Harmful gases and particulates are captured and neutralized, delivering over 95% efficiency in emission reduction.Q: How do these scrubbers ensure compliance with emission standards?

A: Fitted with advanced gas and flow sensors, and designed in line with CPCB/SPCB regulations, the scrubbers measure air quality and gas concentration to maintain effective pollutant removal. Regular monitoring and precise discharge outlet sizing guarantee consistent compliance.Q: What are the benefits of using these modular fume scrubbers?

A: Benefits include reliable emission control, ease of installation and maintenance, excellent corrosion resistance, quiet operation below 60 dB, and flexible customization for application-specific requirements. Industries achieve efficient pollution control and regulatory adherence with minimal disruption to workflow.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Chemical Scrubbers Category

Venturi Scrubber

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Material : Stainless Steel / Mild Steel

Air Flow : Variable; Customizable per process

Power Source : Electric

Efficiency : >98% for fine particulate removal

HDPE Scrubbers

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : High Density Polyethylene (HDPE)

Air Flow : 500 to 40,000 m3/hour

Power Source : Electric (Pump and Blower driven)

Efficiency : >95% removal of particulates and pollutants

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS