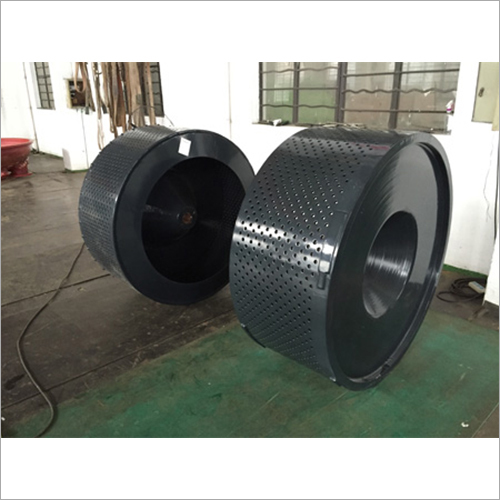

Crusher Cutter

Crusher Cutter Specification

- Efficiency

- High Efficiency Cutting

- Usage & Applications

- Plastic, Rubber, Scrap Crushing & Cutting

- Temperature

- Ambient

- Automation Grade

- Semi Automatic

- Power Source

- Electric

- Instruments Type

- Industrial Machinery

- Orientation

- Vertical

- Product Type

- Crusher Cutter Machine

- Material

- Mild Steel Body with High-Grade Steel Blades

- Cooling System

- Air Cooled Motor

- Noise Level

- Low

- Processing Time

- Variable, Depends on Material

- Capacity

- 100-500 kg/hr

- Voltage

- 220-240 V

- Weight

- Approx 150-300 kg

- Dimension (L*W*H)

- 1200 mm x 800 mm x 1500 mm

- Surface

- Powder Coated

- Installation

- Floor Mounted

- Maintenance

- Easy maintenance, Quick Blade Change Design

- Drive

- Belt Driven

- Feeding System

- Manual/Conveyor

- Number of Blades

- 4 to 8 (Adjustable)

- Color

- Industrial Grey or Custom Color Option

- Cutting Chamber

- Heavy Duty, Corrosion Resistant

- Safety Features

- Overload Protection, Emergency Stop

- Motor Power

- 5-15 HP

- Blade Material

- Alloy Steel, Hardened & Tempered

Crusher Cutter Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 50 Pieces Per Week

- Delivery Time

- 5-7 Days

About Crusher Cutter

Specification

| Brand | Bindica Polyplast |

| Country of Origin | Made in India |

| Mass Scope of Workpiece(kg) | 1000 |

| Max Diameter of Workpiece(mm) | 1600 |

| Distance Between Two Support Bearings(mm) | Min 60 |

| Max Distance between Driving Flange and Right Bearing Support (mm) | 1700 |

| Motor Power (kw) | 4 |

| Torque of Universal Joint Shaft(N.m) | 250 |

| Length of Bed (mm) | 2500 |

| Min Achievable Residual Unbalance Amount(emar) | |

High-Efficiency Cutting for Multiple Materials

Engineered to handle a variety of materials, including plastic, rubber, and scrap, the Crusher Cutter offers exceptional versatility with its high-grade alloy steel blades and adjustable blade configuration. The heavy-duty vertical cutting chamber ensures consistent performance, maintaining high output capabilities while reducing material processing time.

Safety and Reliability in Operation

Safety features such as overload protection and emergency stop ensure secure operation in industrial settings. The belt-driven motor is air cooled, which helps maintain ambient temperatures, and the low noise level contributes to a more comfortable working environment. The machines powder-coated mild steel body enhances durability and resistance to corrosion.

Easy Maintenance & Quick Blade Change

Designed for quick blade changes and straightforward upkeep, this crusher cutter minimizes downtime during regular maintenance. Its floor-mounted installation provides stability, and the intuitive maintenance procedures make it ideal for distributors, service providers, and manufacturers seeking efficiency and reliability.

FAQs of Crusher Cutter:

Q: How does the crusher cutter adjust to different material types and sizes?

A: The crusher cutter features an adjustable blade system, allowing operators to configure between 4 and 8 blades depending on the materials hardness and size. This flexibility ensures optimal cutting performance for plastics, rubber, or scrap materials.Q: What safety mechanisms are incorporated in this machine?

A: Safety is prioritized with features like overload protection and an emergency stop button, preventing accidents and equipment damage during operation. The powder-coated surface and corrosion-resistant components further ensure operator safety and machine longevity.Q: When should maintenance or blade changes be performed?

A: Regular maintenance is recommended after consistent use or when processing throughput decreases. The quick blade change design allows for efficient replacement, minimizing downtime. Detailed intervals depend on material processed and operational frequency.Q: Where is the crusher cutter typically installed and operated?

A: This machine is floor-mounted, designed for factories, recycling plants, and industrial workshops. Its robust construction and compact footprint (1200 mm x 800 mm x 1500 mm) make it suitable for various industrial environments in India.Q: What benefits does the crusher cutter offer to manufacturers and suppliers?

A: With high efficiency, easy maintenance, low noise output, and customizable color options, the crusher cutter enhances productivity and reduces operational costs, supporting manufacturers, suppliers, and distributors with reliable, versatile performance.Q: How is material fed into the crusher cutter during operation?

A: Material feeding can be performed manually or via conveyor for continuous operation. The feeding system is designed for ease of use, supporting both batch and automated processes based on production requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dynamic Balancing Category

Leth Work

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Cooling System : Air Cooling

Automation Grade : SemiAutomatic

Temperature : Up to 70C

Product Type : Leth Work

Center Balancing Machine

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Cooling System : Other, Air Cooled

Automation Grade : Automatic

Temperature : 0C to 45C

Product Type : Center Balancing Machine

Dynamic Balancing Machine

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Cooling System : Other, Air Cooled

Automation Grade : SemiAutomatic

Temperature : Ambient

Product Type : Dynamic Balancing Machine

Dynamic Center Balancing Machine

Price Range 50000.00 - 500000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Cooling System : Other, Air Cooled

Automation Grade : SemiAutomatic

Temperature : 0~45C Operating

Product Type : Dynamic Center Balancing Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS